-

Posts

578 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Events

Gallery

Store

Posts posted by paulguy

-

-

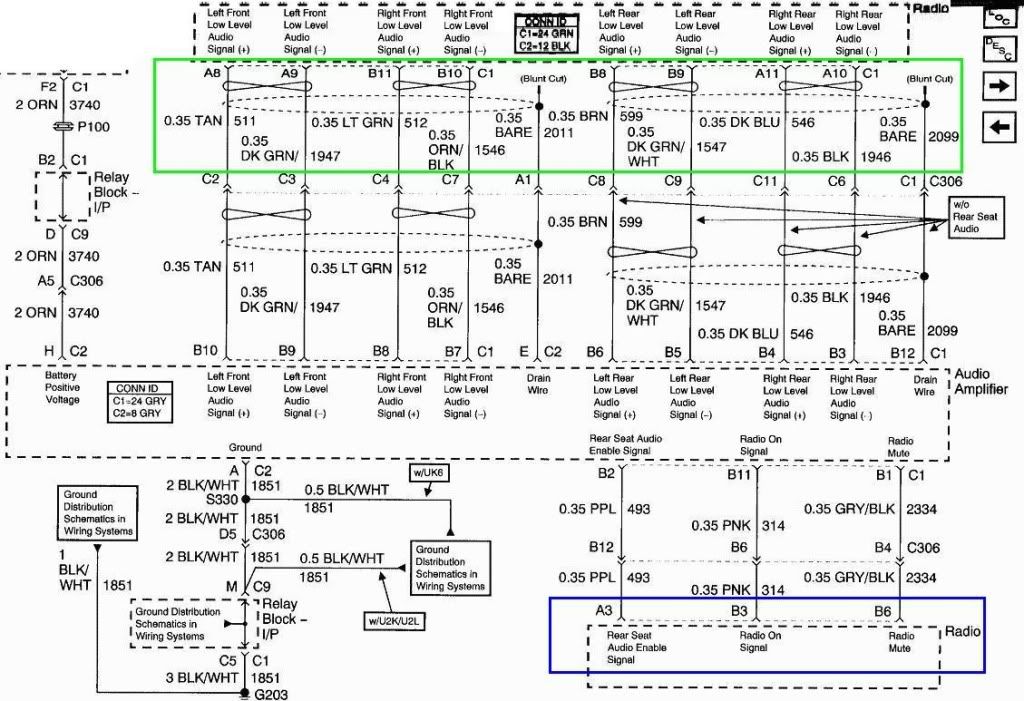

Well, the small white plugs look like a-pillar tweeter plugs, but i`m not sure about those other ones. I think your right when you say your amp isn`t getting power. I`ll post an amp pinout so that you can trace the power and ground to find out if thats what you need.

-

250 amp is alot of juice, I can't see the battery pulling more then that. I'm not sure if getting fuses for bigger then that is going to be easy anyway. I'm not a big fan of breakers myself. They fail.

You didn't have room to put the battery where the aux battery goes under the hood?

-

I think I did a scytex starter/alarm years ago, and if I remember right, it's pretty standard as far as starter/alarms go. Should be pretty easy except for the window module, those can be a bit of work.

If it was me I would probably just run the inverter off of the battery, it might help smooth out spikes in the current, but it probably won't matter either way. How much is a 1000w inverter going to pull anyway?80 amps?

I use a solenoid between both batteries too.

-

IMO this is a must-do mod. And adding a set of HIDs!

Mr. P.

Do you know whats even better?... 2 sets of hids with this mod!

-

-

it should work without the amplifier, there's been guys that have bypassed the amp and they have sound, its just not amplified

Sent from my GT-I9000 using Tapatalk

-

Right on, I should be able to get the job done with two. How long have you been installing? You definitely know your shit. I've been since I was a teenager then became an electrician and still rockin out. This project is going to be my best, well thought out and a lot of customizing.

I've been installing professionally for about 16 years, and working on my own stuff since the mid 80's.

Looks good so far

-

I've done one box under a seat with 10w6's(customers, not mine) and it hit really hard running off a 1000.1 I don't bd meter customers cars. It sounded good though.

-

There is no carpet back there, I mounted wood and carpeted it after because I wanted to cover all of the bare metal.

But the easiest way is to carpet some wood, then munt it

-

Thanks. Glad I could help.

-

Cheers from Alberta.

-

Cheers from Alberta.

-

Welcome

-

Welcome

Nice Dodge...(I think that's the first time I've ever said that!)

At least its not a Ford...(F__king Owner, Really Dumb) hehe.

What times are you running?

-

Any Update? Did you get it working?

-

My HCCA Orion does pretty good for now. 1200 watts @ 1ohm.

-

I don't remember the last box exactly, if i was to guess I would say the box was about '1 to 1.25', which is enough for the w6's and x type;s which are about .65ft. A little dacron and it's close enough.

At least with the x-types, if I want more sound later on, I can run a bigger amp cuz they can handle twice as much power as the jl's.

I just cut a hole and fibreglass over the magnets. Course with jl, you need that 3/4" space over the vent hole on the back of the magnet.

But they're as deep as a w7, so I should just run those, but then I need a new amp for sure with the 3 ohm coils.

-

Hey Paulguy, is all ur stuff mounted directly to the wall? I asked my buddy that's an installer and he was adamant that no matter what length screws I used, they'd come thru the sheetmetal. After looking again, I'm guessing that's what u did, silicone and a piece of board, what insulation is back there. Also I see ur seat back folds down, I'm assuming u cut the tabs?

Silverado777 thanks for the pic.

Thanks again u guys.

The math is simple.... 3/16" to 1/4" thick mounting tab on the amp + 1/2 plywood + carpet + silicone + 3 layers of dynamat(I use b-quiet) = what? over and inch. Probably 1.5"

So as long as you use a screw less then an inch...no problem.

This is truck country here, and I've put amps on probably a hundred cabs and as long as you use silicone that says 'good adhesion', scuff it up and let it set up long enough...no problems.

In fact, I changed mine on my truck and I had to pull for everything I was worth to get the wood off, and I ended up sanding alot of wood off of the back panel.

Insulation is just 3 layers of b-quiet and expanding foam in the rear b-pillars.

Yep, rear seat fold down trick...

-

There's no holes in the back of my cab

-

You don't have to drill holes on the back wall

Just cut a piece of wood to fit between the rear panels behind the back seat, cut the insulation off, and silicone the wood to the back wall.

let it dry for a couple hours...done.

-

I've done 10w6's without lifting the rear seat. The xtypes I think i can do too...but it's gonna be tight

-

Anyone replaced theirs? I took mine out and cleaned it..still makes noise. I wonder how much they are.I don't see them on the online catalogs

-

It the air temperature sender for auto climate controls

And the motors make noise after a while.

-

Will look a lot cleaner, you should try to use the back panel webbing to fish the wires close to the terminals. What subs are you going to install?

Ya I'm not to worried what it looks like. I could have built something custom to flush the amps in but I like to change gear often so that doesn't work when you build it to fit. The only person who sees it is me anyway.

I was happy just to get all the dynamat covered with carpet.

I'm thinking about x-types...not sure yet. My amp is got a fair bit of power at 1ohm. I was thinking about 10w6's like you have, I've built boxes before with them an they hit hard.

But cost from my wholesaler is a fair bit more then i can get other descent subs for.

I'd run hcca 10's if I had the money....big$$$

Xm Receiver

in Radio/Electronics/Security

Posted

I thought that was a dealer only piece.